How Alphasonic Liquid Anilox Cleaning Works

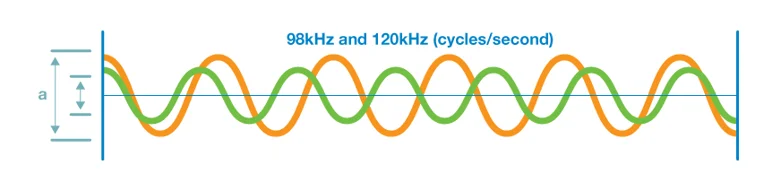

Alphasound is the patented technology allowing for dual frequencies, variable power, and super sweeping ultrasonics to effectively clean aniloxes.

Betasound uses multiple frequencies, variable power, multi-super sweeping ultrasonics to safely and effectively clean aniloxes.

The low-frequency setting will utilize two combined lower frequencies for the regular cleaning of lower LPI aniloxes up to 800 LPI (315 LPC).

The high-frequency setting will utilize combined high frequencies for the regular cleaning of ultra-high line screen anilox rolls as used in high definition flexo of over 800 LPI.

Why "Sweeping" is crucial to Control

A "sweeping circuit" is the attempt to equalize ultrasound in fluid.

Enhanced Super Sweep delivers a more consistent ultrasonic distribution with little variation where competitive technologies struggle to keep sweep rates between 2kHz and 5kHz.

Enhanced Super Sweep guarantees roll safety and ensures rolls are cleaned to 100% of their deliverable volume across the entire web width.

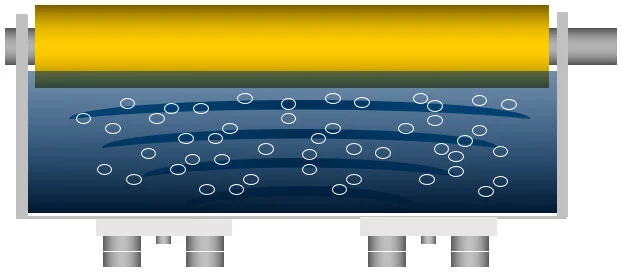

Sonolysis is the use of ultrasonics to accelerate chemical reactions. The bubbles formed during the cleaning process form and grow as they ascend towards the anilox. Once the bubbles contact the anilox surface they implode and the microjet formed in the collapse of those bubbles draws out and draws away the contaminant from the cells.

Alphasonics uses "Active Cavitation" to enhance the effects of sonolysis by re-introducing oxygen into the cleaning tank at strategic points which increases the reaction between the cleaning agent and the contamination resulting in enhanced and faster cleaning.

Learn More About Anilox Cleaning Services