How Does It Work?

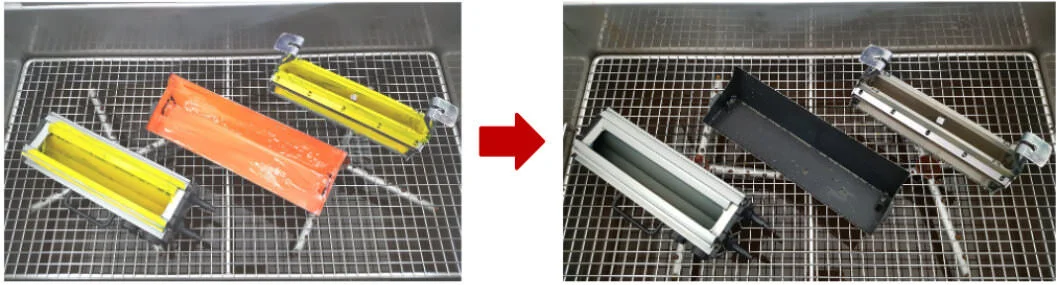

Optimized cleaning results with minimal energy consumption. A patented activation process effective on the nanoscale is utilized in the Nanocleaner. By the focused supply of electric energy, these substances form highly effective, nano-sized particles. They remain active for a few seconds, can penetrate the ink layer, and separate it from the contaminants. The soiled press parts are placed inside the cleaning tank where the activated cleaning agent is continuously sprayed through the jet arms onto the parts. The cleaning takes place in a closed loop under vacuum. This allows for proper cleaning without health hazardous vapors. This allows the Nanocleaners to be installed directly in the production area next to the printing presses.